Industrial vacuum cleaners play a crucial role in maintaining cleanliness and safety in various industrial settings. However, in environments where potentially explosive atmospheres are present due to the presence of flammable gases, vapors, mists, or dusts, the use of non-certified equipment can pose serious risks. This is where ATEX certification comes into play. The “ATmosphères EXplosibles” (ATEX) directive sets forth regulations for equipment and protective systems used in such hazardous areas. This article delves into the significance of ATEX certification for industrial vacuum cleaners operating in potentially explosive atmospheres.

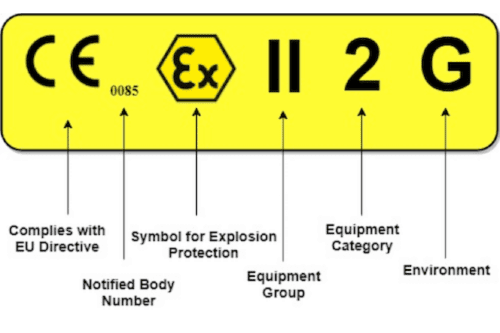

ATEX certification is a legal requirement within the European Union (EU) for equipment intended to be used in environments where explosive atmospheres could occur. The certification ensures that the equipment is designed, constructed, and tested in a way that minimizes the risk of ignition, thereby ensuring the safety of workers, equipment, and the environment.

The primary reason for requiring ATEX certification in industrial vacuum cleaners is to ensure safety. In environments with potentially explosive atmospheres, even a small spark or heat generated by the vacuum’s motor could trigger a catastrophic explosion. ATEX vacuum cleaner are designed with features that prevent sparks, overheating, and other potential sources of ignition.

ATEX-certified vacuum cleaners undergo rigorous testing to ensure they meet strict safety standards. These tests include assessing the vacuum’s ability to withstand and prevent ignition in the presence of flammable substances. By using certified equipment, industries can significantly reduce the risk of accidents, injuries, and damage to property.

Failure to use ATEX-certified equipment in hazardous environments can result in legal penalties and liabilities. Non-compliance not only endangers lives and property but can also lead to costly legal consequences for the organization.

Explosions in industrial settings can have severe environmental consequences, including the release of harmful pollutants and contaminants. ATEX-certified vacuum cleaners help prevent such incidents, thus safeguarding the environment.

ATEX certification ensures that vacuum cleaners are built to withstand the challenging conditions of explosive atmospheres. These certified machines are often more robust and durable, leading to longer equipment lifespans and reduced maintenance costs.

ATEX-certified vacuum cleaners are specifically designed for hazardous environments, meaning they can effectively handle combustible materials without compromising worker safety. This boost work efficiency in industries where vacuuming is necessary for daily operations.

Determine the hazardous zones in your industrial setting where explosive atmospheres are likely to occur. These zones are classified as Zone 0, Zone 1, Zone 2 (gas environments), and Zone 20, Zone 21, Zone 22 (dust environments).

Choose an industrial vacuum cleaner that is designed and certified for the specific hazardous zone in which it will be used. Equipment should be designed to prevent sparks, maintain low surface temperatures, and avoid the buildup of static electricity.

Manufacturers provide documentation indicating that the vacuum cleaner complies with the relevant ATEX directive.

The vacuum cleaner is subjected to testing to ensure it meets the ATEX requirements. Certification bodies conduct assessments to verify compliance.

ATEX-certified vacuum cleaners are marked with appropriate labels indicating their compliance with the ATEX directive. These labels specify the equipment’s intended hazardous zone and provide information about temperature limits, dust classification, and more.

The use of industrial vacuum cleaners in potentially explosive atmospheres necessitates strict adherence to safety regulations. ATEX certification plays a vital role in ensuring that vacuum cleaners are designed, manufactured, and tested to prevent ignition sources. By investing in ATEX-certified equipment, industries can prioritize safety, comply with legal requirements, and contribute to a safer work environment for all. When working in hazardous areas, never compromise on safety – choose ATEX-certified industrial vacuum cleaners to minimize risks and maintain the well-being of your workforce and surroundings.