Professional & Industrial Steam Cleaners

What is Steam Cleaner?

Steam is water which has been changed into a gas. Steam cannot be seen for it is colorless. The cloud of vapor that we see beginning about 2 centimeter from the spout of a teakettle is not steam. The real steam is in the space that seems vacant just outside the spout. The cloud we see is the water that the cooler air has changed from a gas form back into tiny water particles.

Steam is formed by boiling or by evaporation. At sea level water boils when it is heated to 100° C. Water also evaporates at lower temperatures. The steam caused by boiling is as hot as the boiling water. The steam caused by evaporation is not hot. Usually, the word steam refers to hot steam. When water reaches the boiling point, bubbles of the steam begin to rise through it and escape into the air. The temperature will remain at the boiling point until all the liquid has become gas. It requires 100 calories of heat to raise one gram of water from the freezing point (0°C) to the boiling point.

Steam fills more space than the water from which it comes, at the moment when boiling stops, the gas is 1,67 times as great in volume as the former liquid. At this stage it is called saturated steam, if heated more, it takes up even more space. Then it is known as super heated steam. The steam engine is built on this principle.

Our technology

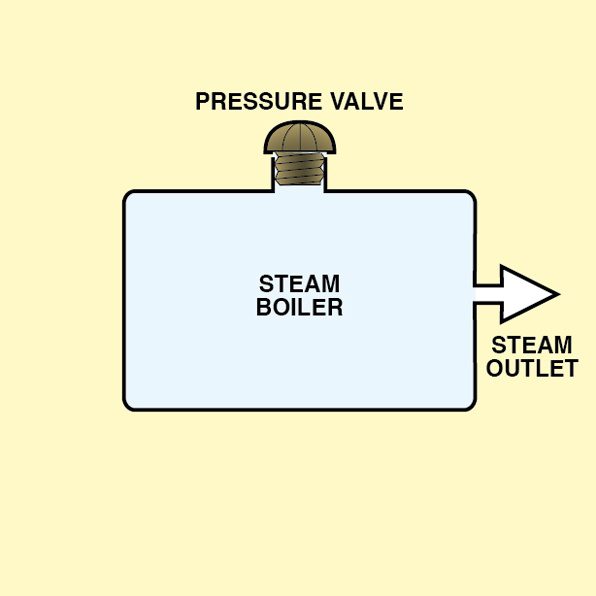

Standard boiler

In the basic version of steam generators, the boiler works also as a reservoir for fresh water. With a load of water you can work about 2 hours (depending on the model). The boiler is always made of anticorrosive and anti-scale 304 stainless steel in order to guarantee duration in time of the steam generator.

In the basic version of steam generators, the boiler works also as a reservoir for fresh water. With a load of water you can work about 2 hours (depending on the model). The boiler is always made of anticorrosive and anti-scale 304 stainless steel in order to guarantee duration in time of the steam generator.

Unlimited autonomy

Steam cleaners with this feature have two water chambers: a pressurized boiler tank and a non-pressurized tank. That allows the operator to add water to the machine while it’s still running. Menikini’s unlimited autonomy steam cleaners are equipped with an electronic level sensor that refills the boiler when the level of water inside it is not enough. As a result, the machines avoid drops in pressure and temperature during use.

Steam cleaners with this feature have two water chambers: a pressurized boiler tank and a non-pressurized tank. That allows the operator to add water to the machine while it’s still running. Menikini’s unlimited autonomy steam cleaners are equipped with an electronic level sensor that refills the boiler when the level of water inside it is not enough. As a result, the machines avoid drops in pressure and temperature during use.

Continuous fresh water inlet

Some of our industrial steam cleaners include an automatic direct water refill that connects the machine to a water pipe and refills the fresh water tank as needed. Continuous water refill systems can also be refilled manually if a water line is not available.

Some of our industrial steam cleaners include an automatic direct water refill that connects the machine to a water pipe and refills the fresh water tank as needed. Continuous water refill systems can also be refilled manually if a water line is not available.

Detergent tanks

These tanks hold and dispense cleaning chemicals. Some of our steam cleaning machines include simple handle controls that allow the operator to control the detergent and steam flow while cleaning.

Benefits of using Menikini Steam Cleaners

1) Ecological

- Conserve water while reducing waste and pollution

- Maintain an environmentally neutral workplace

- Reduce chemical disposal

- Prevent ground water contamination

- Aid in maintaining cleanliness

- Minimize chemical packaging

- Reduce amount of waste products in landfills

- Lower carbon footprint of chemical cleaner production

Sustainability means taking the long-term view of how our actions affect future generations and making sure we don’t cause pollution or deplete resources at rates faster than the earth is able to renew them.

Saturated dry steam is a completely green technology that makes sanitizing possible in an environmentally friendly way without the use of harsh chemicals.

Menikini superheated, saturated dry steam vapor products contribute towards sustainability while saving money on water, chemicals, labour and costly production downtime.

The dry steam contribution

The use of saturated dry steam dramatically reduces water consumption in all domestic and industrial cleaning activities. Menikini technology gets excellent cleaning and sanitizing results saving up to 100 times in washing water, significantly contributing to its conservation.

Chemical free

The pollution and the contamination of the ground and water are a global problem. It is our duty, not just from a moral point of view, to find a solution by investing in applications that drastically reduce the consumption of water and the use of pollutant detergents. Saturated dry steam guarantees an optimal cleaning and sanitizing. It is also an ecological method of deep cleaning as it removes chemical, toxins and dirt without using solvents.

Latent heat transmitted by saturated dry steam from Menikini eliminates all types of pathogenic micro-organisms and harmful bacteria, but does not result in bacterial resistance, as is often the case with chemical disinfectants.

- No ground contamination from unnecessary solvents

- Save time by cleaning without swilling and rinsing

- Avoid allergies and skin irritation

- Protect the taste of food and wine

2) Economical

- Cut labour costs (30% less manpower)

- Reduce water consumption (80% less water)

- Cost savings on waste water purification.

- Reduce disposal costs (90% less detergent)

- Reduce system and line down time

- Reduce toxic waste

- Improve quality inspection

- Use only pure water energy

- Easy and safe to use

- No need to touch dirty areas or chemicals

- Reach into angles and small cracks

- Sanitize as well as clean

- Can be used on electrical parts

The result is a more efficient and profitable cleaning operation.

3) Social

- Improve health, safety and overall appearance of facility

- Reduce exposure to chemicals

- Prevent handling of potentially harmful substances by employees

- Eliminate unpleasant odors

- Improve indoor air quality

- Reduce dirt and dust particles in the air

- Reduce risk of accidents

- Ensure clean, dry and safe walkways

- Minimize workplace noise for anytime cleaning

The result is improved worker and customer safety, enhanced quality of work life and increased occupant satisfaction.