Industrial Vacuum Cleaner

An industrial portable vacuum cleaner is a mobile cleaning equipment designed for industrial and commercial use.

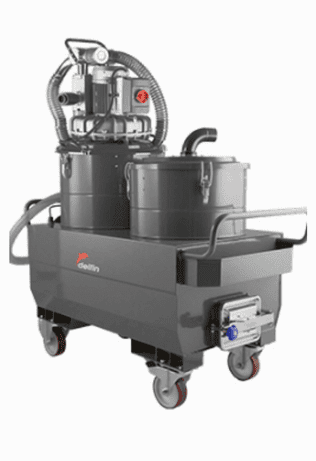

Industrial vacuums for Dust & Solids

Industrial vacuums with Atex certification 3D (Z22)

An Atex vacuum cleaner with 3D (Z22) certification is a specialized vacuum cleaner designed to be used in hazardous areas with explosive atmospheres. Atex Vacuum Cleaner is an essential tool for industries that require the safe collection and disposal of combustible dust and other hazardous materials.

Industrial vacuums for medium-heavy applications

Industrial vacuums for large quantities of material

A large industrial vacuum is typically used to clean large spaces such as factories, warehouses, and construction sites, where there is a high volume of debris, dust, and dirt.

Industrial vacuums Up to 100 liters of liquids capacity

Industrial vacuums Up to 600 liters of liquids capacity

ATEX Vacuum Cleaner is a specialized type of vacuum cleaner designed for use in potentially explosive atmospheres. These vacuum cleaners are certified under the ATEX directives, which set forth strict safety requirements for equipment used in flammable environments. ATEX Vacuum Cleaners are constructed from non-sparking materials and feature explosion-proof motors to reduce the risk of ignition. These specialized vacuum cleaners are commonly used in industries such as petrochemical, pharmaceutical, and food and beverage to maintain a safe and clean working environment. Investing in an ATEX Vacuum Cleaner ensures that you have the necessary equipment to meet safety regulations and keep your employees and workplace protected.

Certified industrial vacuums 1/3D - 1/2D or IECEX

Industrial vacuums for continuous cleaning operations

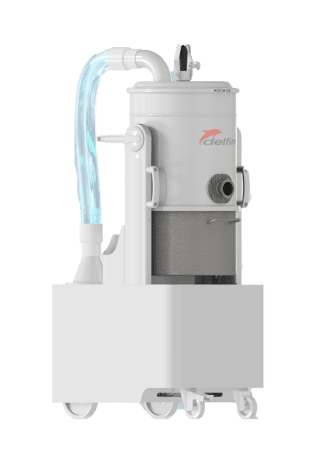

PHARMA20

PHARMA40

MICROTEC

Industrial vacuums for Clean rooms

LC 1000D

LC 1100WD

Industrial vacuum for Direct extraction on board of machineries

DBF

DBFV

AS

AS70

Industrial vacuums for Liquids or dusts and solids

802AIR

452AIR

DM3AIR HD

AIR201

Industrial vacuums with Atex certification 2GD (Z1, 2, 21, 22)

802WD AIREX

352 AIREX

DM3 AIREX

802WET AIREX

Dust Collectors

EV 420

EV 500

EV 560

EV 560 PN

Dust collectors with Atex certification 1/3D - 1/2D

EV 420 1/3D-2D

EV 500 1/3D-2D

EV 560 1/3D-2D

EV560 PN 1/3D-2D

Dust Collectors

CUBE10

CUBE20

CUBE40

TORCH

An industrial dust vacuum cleaner is designed to effectively capture and contain dust, dirt, debris, and other particles generated during industrial processes.

Industrial vacuums for Floor preparation

DM3 EL CLEARAUT

301BAG

DM3PSR

Industrial vacuums for Floor preparation

XTRACTOR 75AF

XTRACTOR 3BP

XTRACTOR 55

PRESEPARATORS

Why Us?

Constromech FZCO is a well-established industrial equipment supplier with 20+ years of experience in UAE. We offer top-quality and dependable products, including industrial vacuums tailored to various industries. Our range of options and knowledgeable team make them the go-to choice for finding the perfect industrial cleaning solution. Constromech is a trusted partner for both compact and heavy-duty industrial vacuums.

0

+

0

%

A

A- Graded SME Company in Dubai

Why Delfin?

Delfin Vacuum Solutions

Delfin Industrial Vacuums are made in Italy, come with a warranty of 2 years, and have over 30 years of experience in designing and producing industrial cleaning equipment.

Here are a few key strengths of Delfin Industrial Vacuums:

Durability: Delfin Industrial Vacuums are made from high-quality materials and are designed to withstand heavy-duty use in industrial settings.

High Suction Power: Delfin Industrial Vacuums provide powerful suction, allowing them to clean even the most challenging materials quickly and efficiently.

Efficient Filtration: Delfin Industrial Vacuums have advanced filtration systems that capture even the smallest particles, protecting the environment and maintaining a clean work environment.

Customization: Delfin Industrial Vacuums are highly customizable, allowing customers to choose the features that best suit their specific needs.

Safety: Delfin Industrial Vacuums have a range of safety features that help to prevent accidents and protect users, including explosion-proof models for use in hazardous environments.

Constromech FZCO is a prominent supplier of industrial vacuum cleaning equipment in the UAE, with a specialization in offering top-quality Delfin industrial vacuum. We are widely recognized as a leading supplier in the region and have earned a reputation for providing reliable and efficient solutions to a range of industries. products.

Selecting the perfect industrial vacuum cleaner requires careful consideration of your specific cleaning requirements, vacuum type, suction power, filtration, durability, operator comfort, maintenance, and safety features.

Vacuum cleaners are essential tools for keeping our homes, offices, and industries clean. When it comes to choosing the right vacuum cleaner for your needs, it’s important to understand the differences between commercial vs industrial vacuums models. Both types of vacuum cleaners are designed for suction of dust particles, but they have distinct features that make them ideal for different types of cleaning tasks.

Industrial vacuum cleaners play a crucial role in maintaining cleanliness and safety in various industrial settings. However, in environments where potentially explosive atmospheres are present due to the presence of flammable gases, vapors, mists, or dusts, the use of non-certified equipment can pose serious risks. This is where ATEX certification comes into play.

Contact Us

Empowering Cleanliness and Safety: The Definitive Guide to Industrial Vacuum Cleaners

Vacuum cleaners are specialized cleaning devices designed for heavy-duty tasks in diverse industrial sectors. Unlike household vacuums, these machines are engineered to tackle challenging cleaning demands prevalent in industrial environments. They feature robust construction, powerful motors, and advanced filtration systems that efficiently capture and manage a wide array of waste materials, ranging from debris and dust to hazardous substances. Their significance spans numerous industries: from manufacturing, construction, and automotive to food processing, textiles, and energy production. In manufacturing, they maintain machinery functionality by eliminating waste; in construction, they ensure safety by removing debris; in food processing, they maintain hygiene by preventing contamination; and in healthcare, they create sterile environments. Ultimately, vacuum cleaners of industrial type play a vital role in promoting cleanliness, safety, and efficiency across various industrial settings.

Vacuum cleaners for industrial purpose hold a pivotal position in maintaining operational excellence and safety across a spectrum of industries. These heavy-duty devices are engineered to handle the demanding cleaning requirements of manufacturing floors, construction sites, food processing plants, and more. By effectively eliminating waste, debris, and contaminants, industrial vacuums not only optimize the working environment for employees but also ensure product quality and compliance with stringent regulations. Their robust design, powerful suction capabilities, and specialized filtration systems collectively make them indispensable tools for industries that demand cleanliness, safety, and precision in their operations.

Types of Industrial Vacuum Cleaners

Vacuum cleaners come in a range of types in industries tailored to specific cleaning needs and environments.

Here’s a further breakdown highlighting some prominent options:

Delfin Industrial Vacuums: Renowned for their extensive product range (over 140 models and 1500 configurations), Delfin offers solutions for diverse industrial applications. Their wet and dry capabilities address cleaning challenges involving both liquids and solids. They prioritize efficiency, hygiene, and safety, making them a reliable choice for various industrial settings.

Dry Vacuum Cleaners: Meant for dust and debris collection.

Wet and Dry Vacuums: Handle both liquids and solids.

Central Vacuum Systems: Ideal for large-scale setups.

Explosion-proof Models: Designed for hazardous environments.

HEPA Vacuum Cleaners: Capture fine particles efficiently.

Oil and Coolant Vacuums: Address liquids like oil and coolant spills.

ATEX-certified Vacuums: Suitable for explosive atmospheres.

Portable Units: Offer versatility for various cleaning tasks.

Backpack Vacuums: Designed for cleaning confined spaces.

Pneumatic Vacuums: Utilize compressed air for cleaning.

Each type caters to specific industries like manufacturing, construction, healthcare, and more. Delfin vacuums, in particular, stand out for their customizable solutions that can be engineered to address unique industrial cleaning requirements.

Key Features to Consider

Essential features of industrial vacuum encompass powerful suction capabilities to efficiently handle debris, advanced filtration systems like HEPA filters to trap fine particles, substantial tank capacities for extended cleaning sessions, and diverse mobility options such as wheeled bases or backpack designs. Additional accessories enhance versatility, aiding in cleaning hard-to-reach areas. Noise levels are a concern, with quieter operation being preferable for worker comfort. Furthermore, features like adjustable airflow and variable power settings provide adaptability for different cleaning tasks. Overall, a balance of these features ensures effective and safe cleaning across diverse industrial settings.

Applications

They have diverse applications spanning manufacturing and production for machinery and workspace cleaning, construction sites for debris clearance, food processing to ensure hygiene, healthcare for sterile environments, automotive and aerospace facilities for operational efficiency, warehousing and logistics for maintaining tidy storage areas, textile production to manage fibers and threads, mining and extraction sites for improved safety, energy and utilities for residue removal, woodworking workshops to handle wood dust, chemicals and pharmaceuticals for safe hazardous material cleanup, aviation and transportation facilities for debris management, wastewater treatment plants for sludge and debris handling, electronic manufacturing to prevent particle contamination, paper and printing industry for paper dust removal, cleanrooms for maintaining controlled environments, and commercial cleaning services for large spaces like malls and stadiums, showcasing their adaptability across a spectrum of industries.

Specific Examples of Delfin Applications:

- Delfin’s Tecnoil series: Efficiently recovers coolant and liquid mixed with metal shavings from machinery, ideal for manufacturing facilities.

- Delfin’s dust extraction vacuums: Capture hazardous dust particles, maintaining air quality in various industrial settings.

Maintenance and Safety

Maintenance and safety are paramount when using industrial vacuums to ensure their efficient operation and the well-being of workers. Maintenance practices include regular inspection of filters, cleaning hoses and attachments, and emptying tanks to prevent clogs and ensure optimal suction power. Proper storage in a clean and dry environment and adherence to manufacturer guidelines are crucial for prolonging the equipment’s lifespan. Safety measures involve training operators on correct usage and appropriate accessories, ensuring proper grounding to prevent static buildup in explosive environments, using appropriate personal protective equipment (PPE) like gloves and masks, and complying with relevant safety regulations such as ATEX for hazardous areas. Regular maintenance not only enhances the machine’s longevity but also ensures consistent cleaning performance, while adherence to safety protocols safeguards against potential hazards, making vacuum cleaners a reliable asset across industries.

Buying Guide

When embarking on the purchase of a vacuum cleaner, a comprehensive buying guide encompasses factors such as the nature of cleaning requirements and workspace layout, requiring a balance between suction power and filtration systems tailored to debris types. Mobility options should align with workspace demands, while a diverse set of accessories aids in versatile cleaning. Noise levels and safety features must be considered, particularly in hazardous environments. Evaluating durability, brand reputation, and user reviews, along with budget considerations and available warranties, ensures a well-informed decision that aligns the vacuum cleaner’s capabilities with the demands of your industry, promoting effective cleaning performance and long-term value.

In conclusion, industrial vacuum stand as indispensable tools across a spectrum of industries, offering versatile solutions for tackling diverse cleaning challenges. Their significance extends beyond mere debris removal, encompassing hygiene maintenance, safety assurance, and operational efficiency enhancement. By effectively addressing various environments and materials, these machines contribute to improved air quality, compliance with regulations, and the overall well-being of workers. When navigating the realm of industrial vacuum selection, a comprehensive buying guide is essential, considering factors such as suction power, filtration efficiency, mobility, safety features, and maintenance requirements. By making informed decisions based on industry-specific needs and practical considerations, organizations can harness the benefits of vacuum cleaners to elevate cleanliness standards, support productivity, and foster a safer and more conducive working environment.